From Concept to Shelf: The Intricate Process of Designing Custom Trophies

Trophies hold a unique place in our culture, symbolizing achievement, recognition, and excellence. Behind every well-crafted trophy lies a fascinating journey that transforms an abstract concept into a tangible, gleaming symbol of accomplishment. Let’s delve into the intricate process of designing custom trophies, exploring the steps involved in bringing these iconic symbols from concept to shelf.

Understanding the Purpose:

The journey begins with a clear understanding of the purpose of the trophy. Whether it’s a sports event, academic achievement, or corporate recognition, the design process is shaped by the intended message and the significance of the award.

Collaboration and Ideation:

Designing a custom trophy is seldom a solitary endeavor. It involves collaboration between designers, clients, and sometimes even the recipients of the award. Brainstorming sessions and ideation workshops help in shaping the initial concepts, drawing inspiration from the essence of the achievement being celebrated.

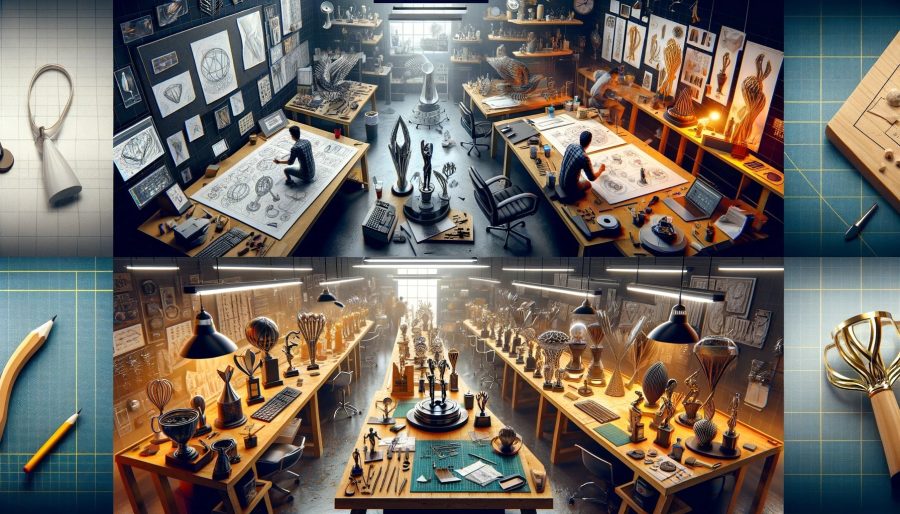

Sketching and Conceptualization:

Once ideas are generated, designers translate them into rough sketches and conceptual drawings. This stage allows for creative exploration, experimentation with shapes, materials, and overall aesthetics. The goal is to capture the essence of the achievement in a visual form that resonates with both the client and the recipients.

Material Selection:

The choice of materials plays a crucial role in the overall design and perceived value of the trophy. Metals, glass, acrylics, and wood are commonly used materials, each offering unique characteristics. The selection is often guided by the design concept, budget constraints, and the desired aesthetic appeal.

Prototyping:

Before mass production begins, a prototype of the trophy is created. This step allows for a physical manifestation of the design, providing an opportunity to assess its feasibility, make necessary adjustments, and ensure that the final product aligns with the initial vision.

Fine-tuning and Approval:

Client feedback and internal reviews lead to further refinements in the design. The goal is to create a trophy that not only reflects the achievement but also aligns with the brand image and values of the organization presenting it. Once the design is perfected, it undergoes final approval before moving into production.

Production and Assembly:

With the approved design in hand, the production phase commences. Skilled craftsmen bring the trophy to life, cutting, molding, engraving, and assembling the various components. Attention to detail is paramount to ensure that the final product meets the highest standards of craftsmanship.

Quality Control:

Quality control measures are implemented throughout the manufacturing process. Inspections, tests, and evaluations are conducted to guarantee that each trophy meets the specified standards and is free from defects.

Packaging and Delivery:

The final step involves carefully packaging the trophies to protect them during transit. Whether the trophies are destined for a local ceremony or an international event, the packaging ensures that they arrive in pristine condition, ready to be proudly displayed on the shelf.

Designing custom trophies is a captivating journey that combines creativity, collaboration, and craftsmanship. From the initial spark of an idea to the gleaming trophy proudly displayed on the shelf, each step in the process contributes to the narrative of achievement and recognition. It is a testament to the dedication of designers and craftsmen who transform concepts into tangible symbols of success.

Leave a Reply

Your email is safe with us.